Boinns one mill is a special machine you can use in the pharmaceutical, food processing, or any other industry for size reduction. It reduces the sizes of large products, which can be hard or medium into small, soft pieces.

Reducing the size of dry material in a product, this increases the surface area of material hence increasing its solubility rate

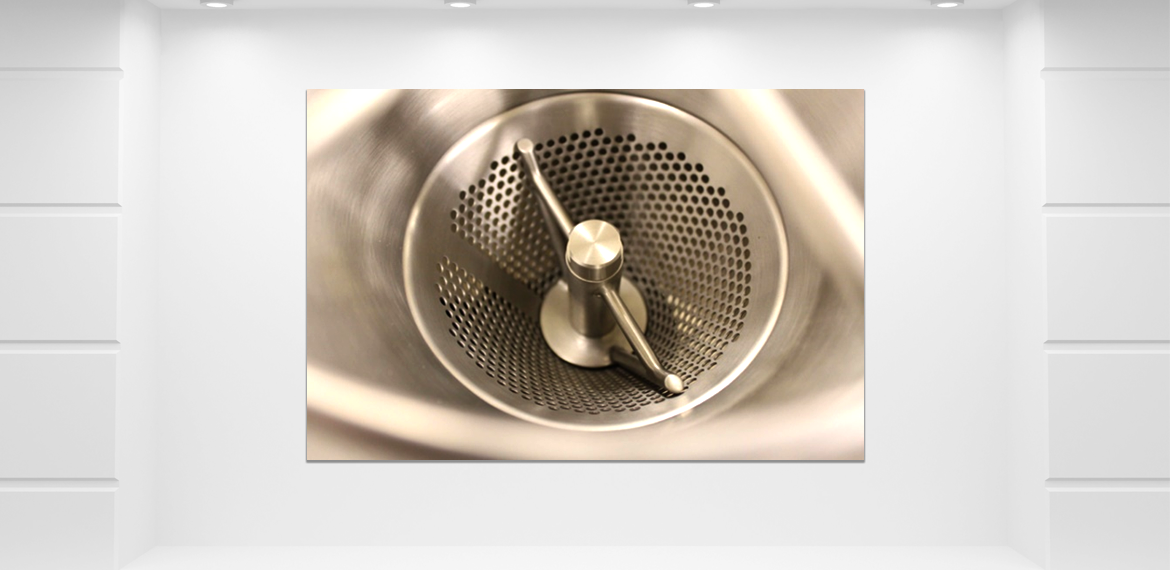

Unprocessed material is loaded into the product inlet of the Cone Mill by hand, gravity-feed or vacuum transfer. The material then passes into the milling chamber where a rotating impeller forces the unprocessed material through stationery cone-shaped screen by a vortex action.

The material is instantly reduced in size as it passes through the holes in the screen. By changing a combination of screen, impeller-shape and speed, the finished milled particle size can be carefully controlled.

Features

- Compact size, Fast screen changes, Easy clean GMP design

- SS 316 contact parts SS 304 Non contact part

- An extensive range of replacement screens are available

- Imported Laser Driller Mesh for Dry application

- Safety Standards with no outside cables

- Vacuum Loading option

- Bin charging Loading system option

- Dust free closed system for charging and discharging of powders or granules

- Different profile of blade and sieve available

- High speed shredding, sizing & grinding

In principle all sizes of our High shear mixer granulator are